Temperature testing is of significant importance and necessity in cutting-edge scientific research, product development, and manufacturing. By conducting temperature testing, the performance of products or materials under various temperature conditions can be comprehensively evaluated and validated. This process helps provide accurate data references for subsequent product design and debugging. It ensures product stability and reliability in different working environments.

In this case, the customer needs to conduct open-loop multi-channel temperature testing on the test object. Based on the customer's testing scenario and actual testing requirements, RIGOL provides a corresponding testing solution.

Open-loop multi-channel temperature testing requires simulating the working environment of the test product at different temperatures to verify if the product can maintain its performance and functionality. This demands that the temperature testing system achieves two functions: firstly, it should be able to simultaneously control the temperature in different areas, simulating the working environment of the product under different temperature conditions. Secondly, it should be capable of temperature detection and data recording for different points within these areas simultaneously, in order to assess the performance and functional behavior of the product.

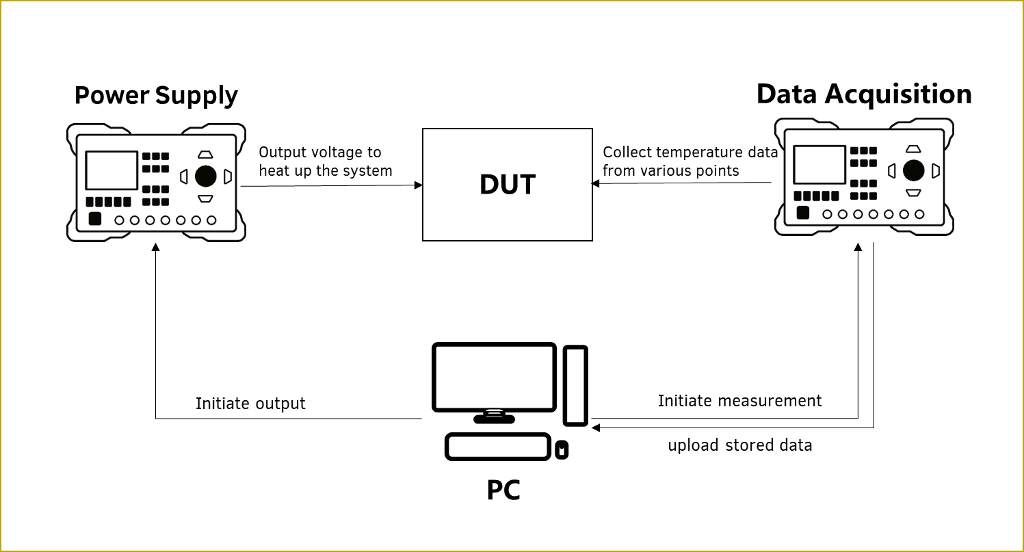

Open-loop multi-channel temperature control testing system diagram

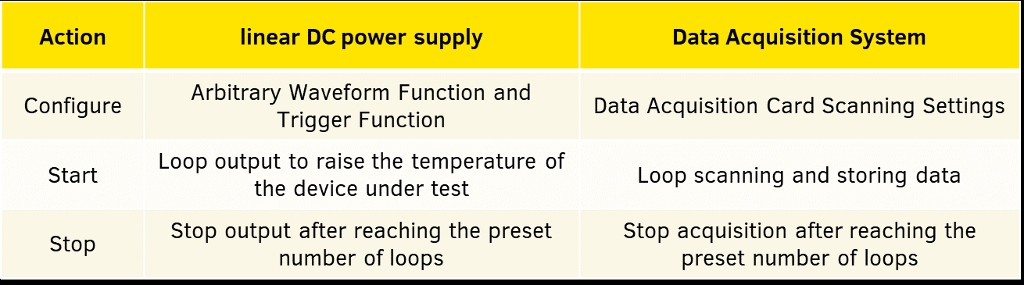

The testing system requires the use of programmable linear DC power supplies to synchronously input voltage to various points of the system under test, causing temperature changes in the test object to simulate its actual working environment temperature. The power supply is required to have multiple outputs and programmable features. Additionally, the testing system also needs to use a data acquisition system to collect temperature data from various points of the system under test. The data acquisition system is required to have multi-channel data acquisition capabilities to achieve automated data collection.

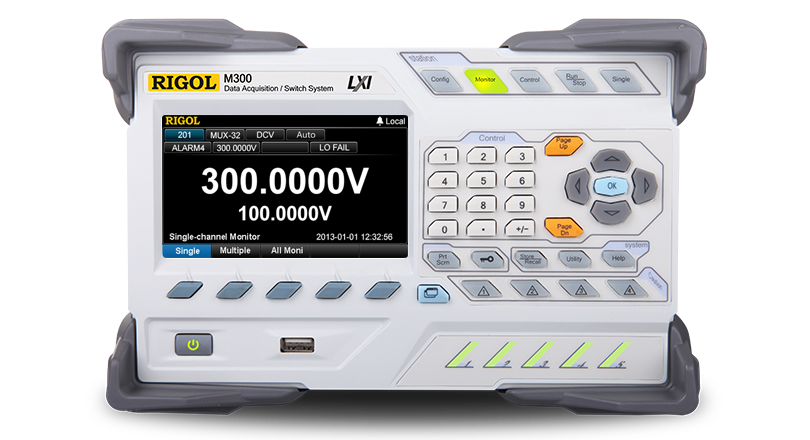

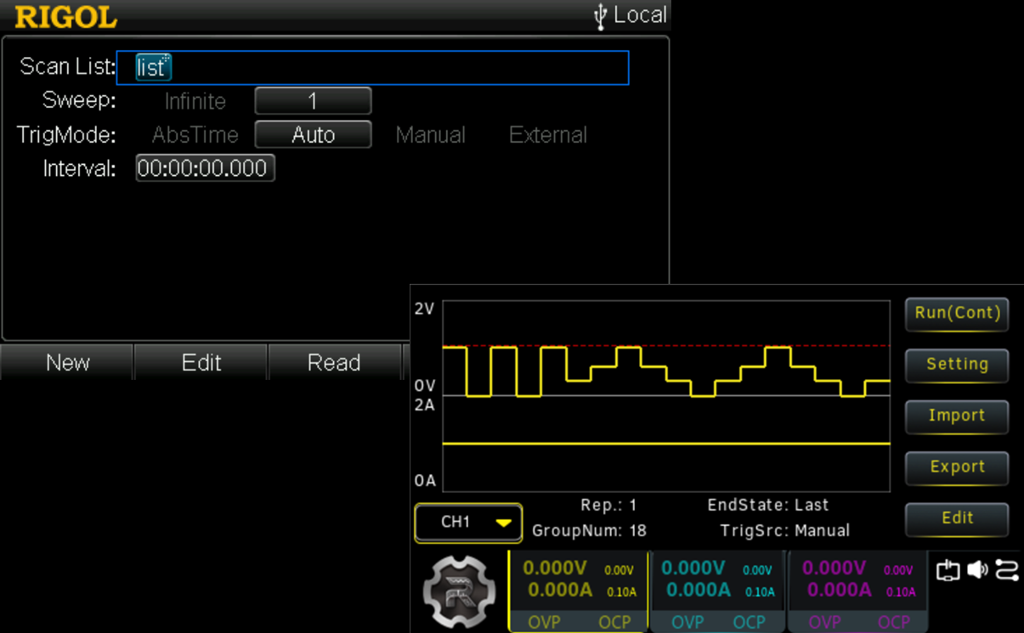

In response to this customer testing case requirement, RIGOL provides support for open-loop multi-channel temperature system testing using RIGOL DP932A programmable linear DC power supply and RIGOL M300 series data acquisition system. This solution utilizes DP932A power supply's arbitrary waveform function to control voltage output, achieving flexible configuration of output sequences through customized arbitrary waveform tables. Open-loop multi-channel testing requires the testing system to operate for a long time. The long-term stability of DP900 series power supplies provides strong support for accurate testing. In addition, the trigger function included in the power supply allows simultaneous control of multiple power supply outputs, ensuring synchronicity within a certain range. The M300 mainframe can provide up to 256 measurement channels, offering excellent and efficient data acquisition capability for product development and industrial production.

Product Support

Temperature Control of the Testing System: RIGOL DP932A Programmable Linear DC Power Supply

Data Acquisition of the Testing System: RIGOL M300 Series Data Acquisition System